Short-range order (SRO) — the arrangement of atoms at small distances within metallic alloys — has been a relatively unexplored realm in materials science. However, the last decade has sparked renewed attention on quantifying SRO, as it plays a vital role in creating customized high-performance alloys, such as those that are stronger or more heat-resistant.

Deciphering the atomic arrangement is no small feat. It usually involves extensive laboratory experiments or complex computer simulations based on imperfect models. These challenges have historically limited the exploration of SRO in metallic alloys.

Enter Killian Sheriff and Yifan Cao, graduate students from MIT’s Department of Materials Science and Engineering (DMSE). Guided by Assistant Professor Rodrigo Freitas and Assistant Professor Tess Smidt from the Department of Electrical Engineering and Computer Science, they are now leveraging machine learning techniques to quantify the intricate atomic configurations constituting SRO. Their groundbreaking research was recently published in The Proceedings of the National Academy of Sciences.

The growing interest in SRO aligns with the excitement surrounding advanced materials known as high-entropy alloys (HEAs). These alloys boast complex compositions that bestow them with exceptional properties.

Traditionally, materials scientists create alloys by starting with a base element, then introducing additional elements in smaller amounts to enhance particular properties. For instance, adding chromium to nickel increases the metal’s resistance to corrosion.

In contrast, high-entropy alloys consist of multiple elements — ranging from three to twenty — in nearly equal proportions. This diversity offers researchers a vast design space. As Cao explains, “It’s like creating a recipe with an abundance of ingredients.”

The aim is to master SRO as a “knob” for fine-tuning material properties by innovatively mixing chemical elements in high-entropy alloys. This method holds promise for various industries like aerospace, biomedicine, and electronics, highlighting the urgent need to investigate different elemental combinations, according to Cao.

Understanding Short-Range Order

Short-range order refers to the tendency of atoms to create specific patterns with particular neighboring atoms. A cursory glance at an alloy’s elemental distribution may suggest a random arrangement, but this is often misleading. “Atoms preferentially associate with specific neighboring atoms, forming defined patterns,” Freitas states. “The frequency and distribution of these arrangements define SRO.”

Grasping SRO is essential for unlocking the potential of high-entropy materials. Unfortunately, the understanding of SRO in HEAs remains limited. Sheriff likens the challenge to constructing a large Lego model without knowledge of its smallest component.

Traditional methods for studying SRO typically rely on small computational models or simulations involving few atoms, which fail to paint a complete picture of complex material systems. Sheriff emphasizes, “High-entropy materials are chemically intricate — effective simulations require a broader scale.” He continues, “It’s like trying to trace your family tree without knowing one of the parents.”

Moreover, basic mathematical calculations have been used to estimate SRO by counting immediate neighbors, yet this technique provides an insufficient view of the phenomena.

Fortunately, researchers are harnessing machine learning to address the limitations of these traditional methods and fully capture and quantify SRO.

Hyunseok Oh, an assistant professor in the Department of Materials Science and Engineering at the University of Wisconsin at Madison, expresses excitement about the potential to investigate SRO in greater depth. Although he was not involved in this study, he focuses on alloy composition and processing methods’ impact on SRO, aiming to design superior alloys. “The physics of alloys and their properties’ atomistic origins are interlinked with short-range ordering, but achieving accurate calculations has proven nearly impossible,” says Oh.

A Dual Machine Learning Approach

To delve into SRO with machine learning, think of the crystal structure of high-entropy alloys as a connect-the-dots puzzle, as Cao describes. “Knowing the rules for connecting dots is essential to reveal the pattern.” Moreover, a comprehensive simulation capturing all atomic interactions is necessary for clarity.

The initial step toward understanding these rules involved replicating chemical bonds within high-entropy alloys. “Variations in energy related to chemical patterns affect short-range order, yet we lacked a robust model to address this,” Freitas mentions. The model developed by their team serves as the cornerstone for accurately quantifying SRO.

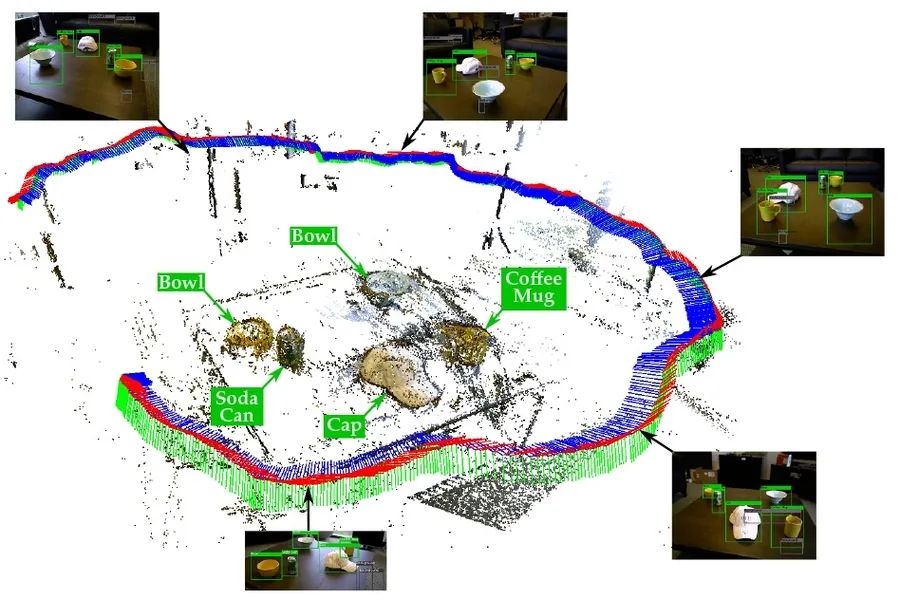

The second challenge, capturing the entire picture, was more intricate, given that high-entropy alloys can exhibit billions of chemical motifs — combinations of atom arrangements that may appear differently yet contain equivalent bonds. The team tackled this issue using 3D Euclidean neural networks, allowing them to identify chemical motifs from high-entropy material simulations with unprecedented accuracy, examining them atom by atom.

The final step involved quantifying the SRO, wherein Freitas used machine learning to assess the various chemical motifs, assigning each a numerical value. When researchers need to quantify the SRO in a new material, they can input it into the model, which sorts it, returning an answer from its database.

The team also dedicated time to enhance the accessibility of their motif identification framework. “We have compiled a sheet featuring all possible permutations of SRO, each linked to its corresponding number through this machine-learning process,” Freitas explains. “In future simulations, we can use this to quickly assess the anticipated SRO.” The neural network efficiently recognizes symmetry operations, tagging equivalent structures accordingly.

“Compiling all the symmetries manually is labor-intensive. Machine learning accelerated this process and made it practical,” Freitas concludes.

Accessing the World’s Fastest Supercomputer

This summer, Cao, Sheriff, and their team will leverage the U.S. Department of Energy’s INCITE program to explore how SRO evolves under standard metal processing conditions, such as casting and cold-rolling, utilizing the Frontier supercomputer, the world’s fastest.

“To comprehend how short-range order shifts during metal manufacturing, a high-quality model and expansive simulation are crucial,” Freitas emphasizes. Their existing strong model now combines with INCITE’s advanced computing facilities for comprehensive simulations.

“This research will likely reveal mechanisms for metallurgists to create alloys with predetermined SRO,” Freitas adds.

Sheriff is enthusiastic about the numerous possibilities this work presents. One notable advantage is the 3D data accessibility regarding chemical SRO. While traditional methods are limited to two-dimensional insights, physical simulations can effectively fill in the gaps, granting comprehensive 3D information.

“We’ve established a framework to discuss chemical complexity,” Sheriff elaborates. “By gaining this understanding, we can draw from the wealth of materials science related to classical alloys to develop predictive tools for high-entropy materials.”

This progress may pave the way for the intentional design of advanced materials, rather than relying on chance.

Funding for this research came from the MathWorks Ignition Fund, the MathWorks Engineering Fellowship Fund, and the Portuguese Foundation for International Cooperation in Science, Technology, and Higher Education in the MIT–Portugal Program.

Photo credit & article inspired by: Massachusetts Institute of Technology