Did you know that six in ten Americans struggle with at least one chronic disease? Furthermore, four in ten are managing two or more chronic illnesses. For individuals dealing with conditions like hypothyroidism and inflammatory diseases, tracking specific blood tests is crucial for effective management. However, traditional methods often involve the hassle of scheduling appointments, journeying to hospitals, and waiting for lab results—an exhausting cycle for many.

Enter SiPhox Health, a pioneering company aiming to transform how patients and physicians tackle chronic illnesses from the comfort of their own homes. Their cutting-edge blood testing technology utilizes a silicon photonic chip, approximately the size of a coffee maker, capable of accurately measuring 20 different biomarkers.

While this innovative device is still in the research phase and awaiting FDA clearance, SiPhox currently offers mail-in blood testing powered by approved technologies. The company aims to expedite test results and expand access to patients across the nation.

“Many people skip blood tests due to inconvenience,” explains Michael Dubrovsky, SiPhox’s founder and former MIT researcher. “This leads to doctors relying on symptoms, which isn’t optimal for managing chronic diseases.”

Dubrovsky teamed up with co-founder Diedrik Vermeulen at MIT, where they explored the realms of photonic chip and laser technologies. Their vision revolves around creating smaller, more efficient devices that can be easily scaled.

“Traditional biolabs use large, complex equipment filled with expensive optics and lasers for blood testing,” Vermeulen states. “Our approach retains those essential features but condenses them onto a chip, making the process scalable enough to be used at home. Think about how computers evolved from room-sized machines to compact devices! We’re doing the same with blood testing.”

Innovative Photonic Chips Revolutionizing Health Monitoring

Dubrovsky and Vermeulen’s partnership blossomed at MIT in 2019, where their shared vision led to significant breakthroughs in optical chip design.

“We envisioned optical chips functioning more like printed circuit boards, where multiple chips reside on one board,” Vermeulen elaborates. “This combination enables us to create a new breed of optical circuits.”

The duo frequently met at the Martin Trust Center for MIT Entrepreneurship, refining their concept and filing patents by February 2020. Their path led them to the START.nano program, providing access to MIT.nano’s advanced laboratories and equipment aimed at accelerating innovation.

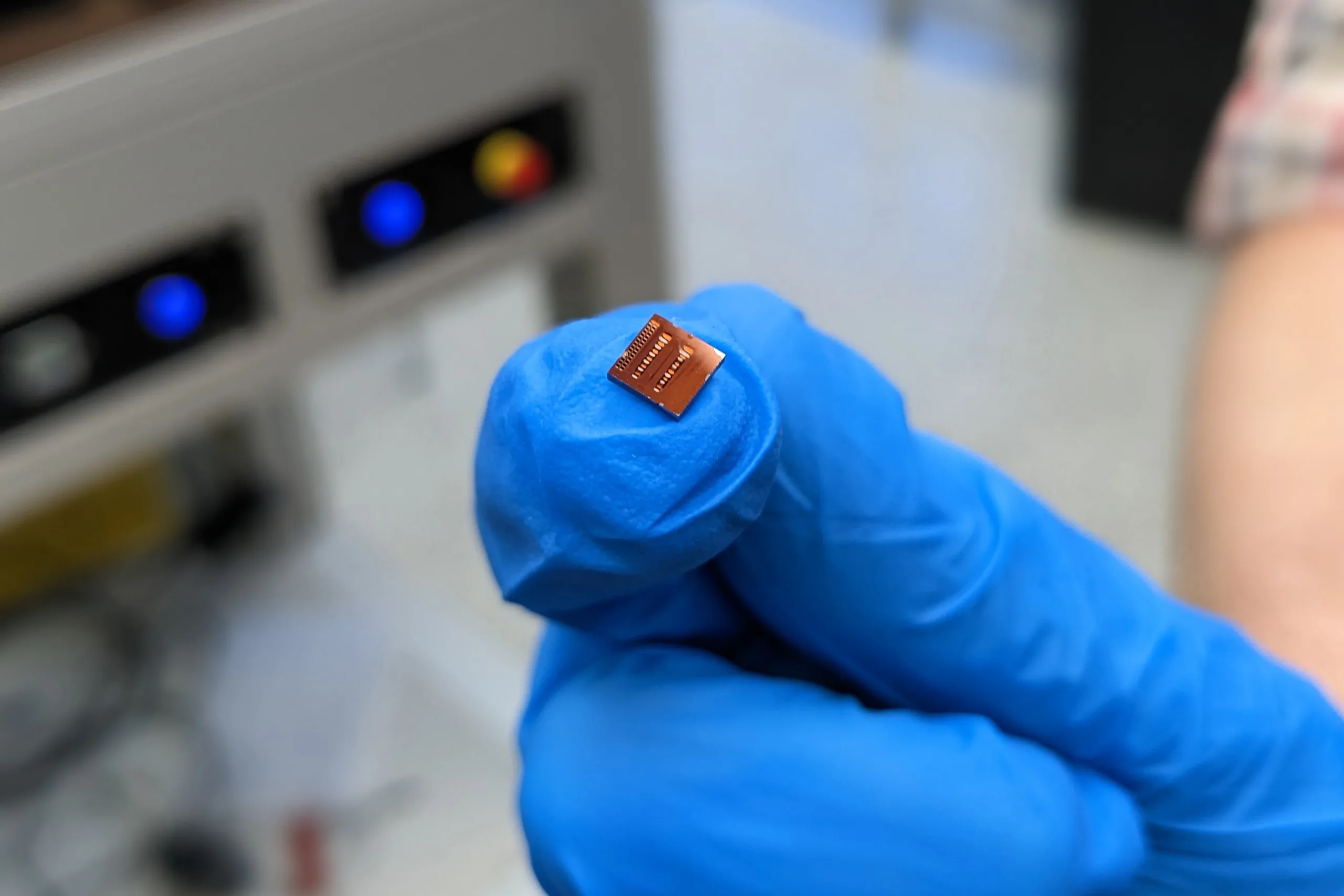

The same lasers used to manufacture traditional silicon chips also facilitate the production of SiPhox’s integrated photonic chips. Each chip, measuring just 1 millimeter, incorporates a variety of optical components typically found in standard lab systems, yet at a cost-effective price point suitable for single-use applications.

As they explored potential applications for their technology, the Covid-19 pandemic offered a new perspective.

“We pivoted our focus toward biosensing, developing both disposable and reusable chips,” Vermeulen shares.

Initially targeting infectious diseases, they soon recognized their technology’s potential for high-precision blood testing instead.

“With my background in tunable lasers at MIT, we implemented our experiences to design something innovative from scratch,” Vermeulen adds.

SiPhox’s testing system operates seamlessly with third-party arm patches that patients can use to collect blood samples at home. Dubrovsky likens the experience to using a Nespresso machine: simply pop in a pod and push a button. Each disposable cartridge is equipped with an array of photonic immunoassay sensors that target specific proteins or hormones.

The system also features a user-friendly dashboard where both patients and physicians can access biomarker data in real-time. It not only displays current results but also houses historical data and educational resources for better understanding various biomarkers. Additionally, SiPhox leverages advanced language models to integrate traditional blood test data alongside its innovative results.

Thanks to their semiconductor laser and silicon chip approach, a single traditional manufacturing facility could potentially churn out up to 1 billion SiPhox chips monthly.

“Our technology’s scalability comes from its chip-based design,” Vermeulen explains. “While simpler mass production can be achieved via injection molding, our complex technology thrives on integrated silicon chips.”

Paving the Way for a Healthier Future

Dubrovsky and Vermeulen envision a future where monitoring health metrics is as routine as daily dental hygiene. This vision carries significant implications for millions of Americans who depend on regular blood tests for chronic disease management.

“For individuals with inflammatory conditions, monitoring inflammation levels is vital, as untreated flares can render medication ineffective,” Dubrovsky emphasizes. “Catching a flare-up early can significantly improve quality of life.”

To secure FDA clearance, SiPhox is preparing to commence studies in the upcoming months. The accuracy of its system has already garnered validation from third-party evaluations, and the company’s facility in Burlington, Massachusetts, can produce around 10,000 cartridges monthly.

Once FDA approval is achieved, SiPhox plans to collaborate with health systems, insurers, employers, and mail-in testing companies to broaden accessibility to their health monitoring solution.

“Our device can offer individuals a transformative approach to health care at home,” Vermeulen concludes. “Once established, users can access telehealth services enabled by our blood testing technology, akin to how Apple users enjoy diverse apps—SiPhox users will also benefit from curated health services integrated with our core capabilities.”

Photo credit & article inspired by: Massachusetts Institute of Technology