In industries such as cement, steel, chemicals, or paper production, generating substantial heat is crucial. Traditionally, this heat has been produced by burning fossil fuels, a practice that has significant environmental repercussions.

To tackle the emissions problem in manufacturing, some innovative startups are rethinking those processes. Daniel Stack, a graduate of MIT, is determined to revolutionize industrial heating by changing the heat source altogether.

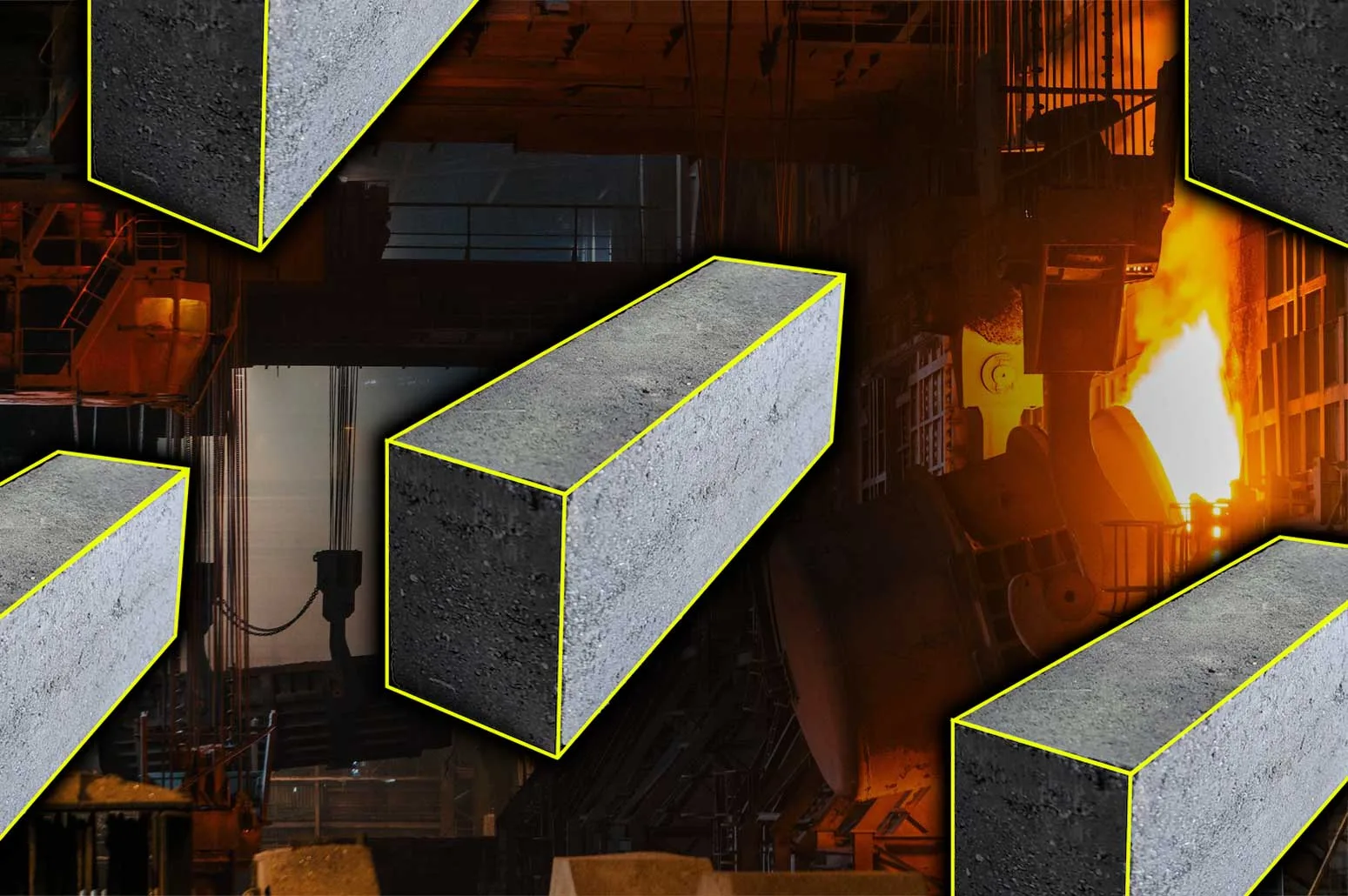

Since he began his journey at MIT in 2014, Stack has focused on developing thermal batteries that utilize electricity to heat specially designed ceramic firebricks. These bricks, known for their longstanding efficacy as heat stores, have reached a new level of performance. In 2021, Stack co-founded Electrified Thermal Solutions, which has showcased its firebricks’ ability to efficiently store heat for several hours and release it at astonishing temperatures of up to 3,272 degrees Fahrenheit — a game changer for challenging industrial applications.

This breakthrough capability to achieve temperatures exceeding 3,000 F opens the door for some of the hardest sectors to decarbonize. By harnessing renewable energy, industries can now transition to sustainable practices while saving costs by utilizing electricity when it is abundant and cheap.

“At Electrified Thermal, we maintain a global outlook, yet we see incredible opportunities in the U.S. energy landscape,” explains Stack. “In places within the wind belt, electricity prices can be negative for more than 20% of the year, making it feasible to tap into this low-cost, clean power.” This innovative approach could level the playing field with fossil fuels, not only in terms of price but also through significant climate benefits.

Reimagining a Classic Technology

Stack’s academic focus shifted dramatically after he joined MIT’s Department of Nuclear Science and Engineering. “I originally aimed to work on state-of-the-art nuclear reactors, but I soon found myself captivated by the concept of heating bricks,” Stack comments. His advisor, Charles Forsberg, opened his eyes to the potential of energy storage in aiding the entire energy transition.

Firebricks, inexpensive clay products, have been utilized in various heating applications for centuries. In a pivotal 2017 paper co-authored by Stack and Forsberg, they outlined firebricks’ capacity to store renewable energy, albeit using traditional electric resistance heaters that limited their thermal output.

During his doctoral studies, Stack collaborated with Forsberg to enhance the firebricks’ functionality, making them electrically conductive. By eliminating the need for electric resistance heaters, these innovative bricks could directly generate heat.

“The problem with electric heaters is longevity and heat generation capacity,” Stack elaborates. “Firebricks are incredibly cost-effective and can withstand extreme temperatures for extended periods.” Their specially formulated conductive bricks remain 98% similar to conventional firebricks, enabling scalable production using existing manufacturing techniques.

As his PhD progressed, Stack recognized the commercial viability of his invention. He engaged with the MIT Sloan School of Management, participated in the StartMIT and I-Corps programs, and secured support from the U.S. Department of Energy.

“Thanks to the vibrant Boston and MIT ecosystems, along with the Department of Energy’s backing, we successfully spun out our solution from the lab—the electrically conductive firebrick or ‘e-Brick,’” Stack remarks.

Electrified Thermal encapsulates its firebrick arrays within insulated metal units. Their standard system can collect and release about 5 megawatts of energy and store roughly 25 megawatt-hours. They have demonstrated the capability of generating significant heat and are currently fine-tuning their system from their base in Medford, Massachusetts, with substantial funding—over $40 million—backing their mission to scale.

“Our electric heating solution can outperform anything currently available on the market,” Stack emphasizes. “This allows for the replacement of fossil fuels in many industrial environments that struggle to decarbonize.”

Addressing a Global Challenge

Electrified Thermal is now collaborating with numerous industrial sectors, including cement, steel, glass, and chemicals. “The challenge of industrial heating is universal,” Stack observes. “Every sector faces the same critical need to obtain heat affordably and with zero carbon emissions in mind as we transition toward sustainable energy.”

Currently, the company is working on a commercial-scale system, targeting launch in the upcoming seven months. “Next year will be pivotal,” Stack states. “We will showcase operational capabilities that various industries require, leading to potential implementations at customer sites by year’s end.” This achievement in electric heating is unprecedented as it promises to deliver heat at unparalleled temperatures.

By partnering with manufacturers in the production of their firebricks and systems, Electrified Thermal aims to facilitate rapid deployment across the sector at minimal costs.

“From the inception of our e-brick design, we prioritized scalability within existing manufacturing processes,” Stack asserts. “To decarbonize heavy industries, efficiently converting zero-carbon energy to heat presents the most economical route forward. Our goal is to emerge as the leading technology that unlocks this potential, facilitating the flow of significant global energy through our systems as we advance the energy transition.”

Photo credit & article inspired by: Massachusetts Institute of Technology