Muscles are nature’s incredible actuators, expertly converting energy into motion with remarkable strength and precision, especially considering their size. Unlike synthetic actuators, muscle fibers possess the unique ability to self-repair and enhance their strength through consistent exercise.

This remarkable resilience and adaptability lead engineers to harness natural muscles in robotic designs. Recent strides have been made in creating “biohybrid” robots that utilize muscle-powered actuators to facilitate movement in artificial skeletons—robots that can walk, swim, pump, and grip. However, the complexity of each robot’s design has made it challenging to establish a universal framework for optimizing muscle function across various robotic configurations.

In response, MIT engineers have introduced a groundbreaking spring-style device, referred to as a “flexure,” which can serve as a foundational structure suitable for diverse muscle-powered robots. This innovative spring is specifically engineered to enhance the work output of attached muscle tissues. Think of it as a leg press machine, calibrated for maximum effectiveness, enabling muscles to produce greater movement.

In their experiments, the researchers discovered that when muscle tissue was fitted onto the flexure, resembling a rubber band encircled around two posts, it repeatedly and consistently pulled on the spring. Astonishingly, this setup facilitated muscle extension five times greater than prior actuator designs.

The flexure represents a pioneering building block that can interconnect with additional flexures to create adaptable skeleton configurations. Engineers can thereby integrate muscle tissues to power their robotic movements effectively.

“These flexures act as a versatile skeleton, allowing muscle actuation to drive motions across multiple directions predictably,” explains Ritu Raman, the Brit and Alex d’Arbeloff Career Development Professor in Engineering Design at MIT. “We’re equipping roboticists with a fresh toolkit for crafting powerful, precise muscle-driven robots capable of fascinating tasks.”

Today, Raman and her colleagues detailed their groundbreaking flexure design in a study published in the journal Advanced Intelligent Systems. Co-authors from MIT include Naomi Lynch ’12, SM ’23; undergraduate Tara Sheehan; graduate students Nicolas Castro, Laura Rosado, and Brandon Rios; alongside mechanical engineering professor Martin Culpepper.

The Mechanics of Muscle Pull

When muscle fibers are left to contract autonomously in a petri dish, they tend to move in unpredictable and chaotic ways, offering little practical application. As Raman aptly notes, “When detached, the muscle essentially flails around in liquid.”

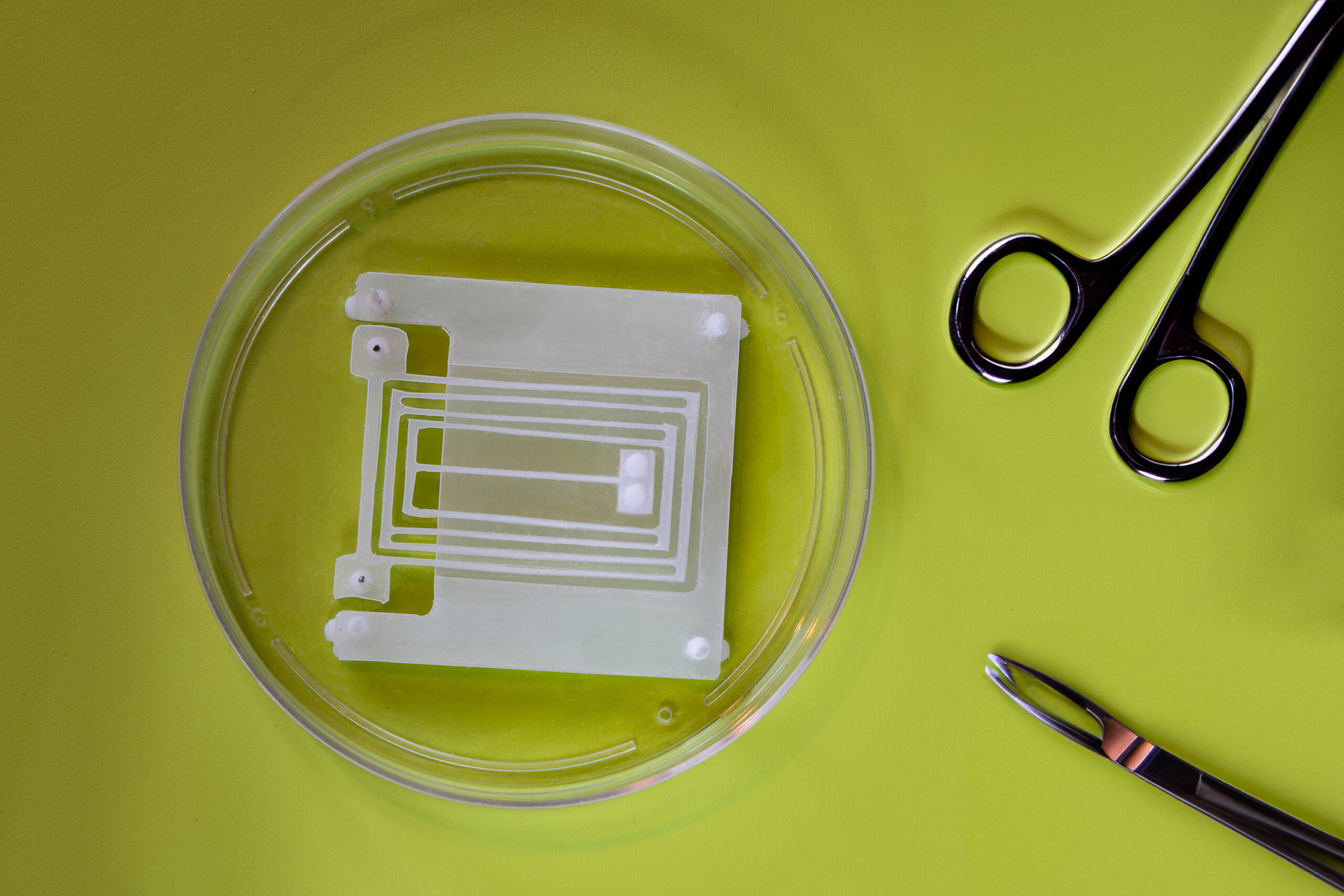

To channel muscle function into a mechanical actuator, engineers typically position a strip of muscle between two flexibly anchored posts. As the muscle band contracts naturally, it bends the posts, fostering some degree of movement to potentially power robotic structures. However, past designs have struggled with efficiency due to variability in muscle contractions, often resulting in inconsistent movement.

Raman’s research team sought to create a skeleton that amplifies and focuses muscle contractions, allowing for greater control over movement. “Our goal was to design a skeleton that optimally utilizes the force generated by muscles,” she says.

The methodology focused on the multidirectional nature of muscle contractions. The researchers concluded that if a muscle is required to pull two posts closer together in a specific direction, those posts should be connected to a spring that exclusively allows movement in that trajectory.

“We needed a structure that was supple in one direction, yet rigid in others, ensuring muscle contractions converted maximally into directional motion,” adds Raman.

The Innovation of Soft Flexures

In Professor Martin Culpepper’s lab at MIT, Raman uncovered various devices that fit this description. Culpepper’s team specializes in designing high-precision machine elements, from actuators to bearings, to facilitate refined movement and control in engineering applications. Among these are flexures, spring-like components composed of parallel beams that can flex with precise motion.

“By manipulating the thickness and spacing of these beams, we’re able to adjust the flexure’s stiffness,” Raman explains. Working alongside Culpepper, she designed a flexure optimized for muscle contraction, resulting in an effective configuration and stiffness to allow for maximal stretching of the spring.

The flexure’s unique design is one-hundredth as stiff as muscle tissue itself, resembling a miniature accordion pinned to a base at each corner. The muscle band, crafted from live mouse muscle fibers, is then wrapped around these posts to measure contraction effectiveness.

The team found that this innovative flexure allowed muscle contractions to align predominantly with the intended direction of motion, achieving a pulling distance five times greater than earlier designs.

“The flexure we devised is highly flexible in one direction while remaining rigid in all others,” Raman explains. “As the muscle contracts, every ounce of force translates into directional movement, culminating in significant amplification.”

Beyond optimizing robotic muscle performance, the researchers are also using this platform to assess muscle endurance. By varying the frequency of muscle contractions, they gained insights into muscle fatigue and the potential for endurance training.

“Understanding how quickly muscles fatigue, and how we can enhance their endurance, is a pivotal outcome of our research,” notes Raman.

The team is now poised to adapt and integrate flexures into sophisticated, articulated robots powered by natural muscle tissues.

“We envision creating a surgical robot capable of performing minimally invasive procedures internally,” says Raman. “While muscles can indeed power robots of any size, our focus is particularly on developing compact robots, as that’s where biological actuators shine in terms of strength, efficiency, and adaptability.”

Photo credit & article inspired by: Massachusetts Institute of Technology