Car design is a proprietary and iterative process, often taking several years for manufacturers to refine 3D models digitally. Carmakers diligently adjust designs through simulations before constructing prototypes for physical tests. Unfortunately, specific test details and specifications, including aerodynamics, generally remain confidential. As a result, major strides in performance—whether that be fuel efficiency improvements or extended electric vehicle range—can become slow and isolated between manufacturers.

However, engineers at MIT propose that leveraging generative artificial intelligence tools can drastically expedite the search for improved car designs. These advanced AI systems can analyze extensive datasets in mere seconds, uncovering correlations and generating innovative designs. While such tools are available, the crucial data needed for their training had often been fragmented or inaccessible.

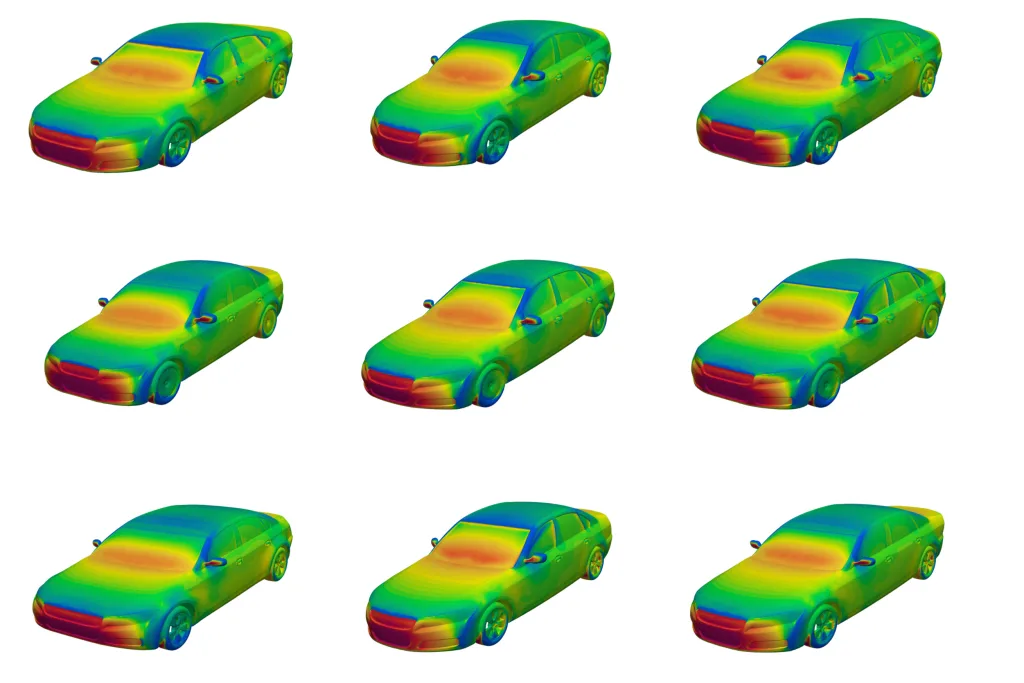

Now, MIT engineers have unveiled a remarkable dataset, known as DrivAerNet++, which is openly accessible for the first time. This groundbreaking dataset includes over 8,000 car designs, crafted from the most common vehicles in circulation today. Each design boasts a 3D representation and detailed aerodynamics information derived from thorough fluid dynamics simulations conducted for every individual design.

Credit: Courtesy of Mohamed Elrefaie

Each of the 8,000 designs is available in multiple representations, including mesh, point cloud, or a comprehensive list of design parameters and dimensions. This diverse approach allows various AI models, fine-tuned to interpret specific data formats, to utilize the dataset efficiently.

DrivAerNet++ stands as the most extensive open-source dataset for car aerodynamics ever created. The engineering team envisions it as a vital resource for developing realistic car designs while offering comprehensive aerodynamics data that can quickly train AI models. These models could then generate novel designs significantly faster than the current automotive industry standards, potentially leading to more fuel-efficient vehicles and electric cars with enhanced range.

“This dataset establishes a foundation for the next generation of AI applications in engineering, fostering efficient design processes, reducing R&D costs, and promoting advancements towards a more sustainable automotive future,” explains Mohamed Elrefaie, a mechanical engineering graduate student at MIT.

Elrefaie and his colleagues are set to present their findings and discuss applicable AI methodologies at the upcoming NeurIPS conference in December. His collaborators include Faez Ahmed, an assistant professor of mechanical engineering at MIT, Angela Dai, an associate professor of computer science at the Technical University of Munich, and Florin Marar from BETA CAE Systems.

Bridging the Data Gap

Ahmed, who leads the Design Computation and Digital Engineering Lab (DeCoDE) at MIT, and his team are focused on harnessing AI and machine-learning tools to optimize the design of complex engineering systems, especially automotive technology.

“Designing a car traditionally involves such high costs that manufacturers often make only slight modifications from one version to the next,” Ahmed notes. “However, having access to expansive datasets with performance metrics for each design allows machine-learning models to iterate rapidly, increasing the likelihood of producing superior designs.”

Timeliness is crucial as the automotive industry strives to innovate, especially given its significant environmental impact.

“Now is the perfect moment to accelerate car innovations, as vehicles are among the largest polluters globally. The quicker we can reduce emissions, the more we can benefit our climate,” adds Elrefaie.

When examining new car design processes, the researchers identified that even though AI models exist to generate optimal designs swiftly, available car data has historically been sparse. Previous efforts produced limited datasets of simulated designs, and car manufacturers rarely disclose the specifications for their tested models.

To address this data deficiency, specifically regarding car aerodynamics—which is vital for setting electric vehicle range and internal combustion engine fuel efficiency—the team sought to create an extensive dataset of thousands of accurately represented car designs, without having the luxury of conducting physical tests.

Beginning with 3D models from Audi and BMW provided in 2014, the researchers utilized these models to form three primary categories of passenger cars: fastback, notchback, and estateback. These foundational models serve as a springboard for exploring new designs, balancing simplicity and complexity.

A Comprehensive Library of Car Designs

The new study involved applying morphing techniques to these baseline car models, systematically adjusting 26 parameters such as length, body features, windshield pitch, and wheel design. Each unique configuration was classified as a distinct car design and added to the growing dataset. Optimization algorithms were employed to ensure the uniqueness of each design, preventing duplicates.

Complex computational fluid dynamics simulations were also executed to understand airflow interaction with each car design. This substantial undertaking culminated in over 8,000 distinct, physically accurate car designs representing the most prevalent passenger vehicles today.

In total, the project utilized over 3 million CPU hours on the MIT SuperCloud, generating a staggering 39 terabytes of data—equivalent to a sizable fraction of the entire print collection of the Library of Congress.

Researchers now have a powerful resource at their fingertips to enhance AI model training. For example, models could focus on parts of DrivAerNet++ to identify configurations that achieve optimal aerodynamics. Within seconds, these models could deliver innovative car design suggestions derived from the dataset’s extensive and accurate designs.

The dataset may also serve inverted objectives. After training, researchers can input specific car designs into the model to quickly evaluate their aerodynamics, providing insights into potential fuel efficiency or electric range—all without the financial burden of physical testing.

“This dataset enables the training of generative AI models to perform tasks in seconds instead of hours,” Ahmed concludes. “This capability could significantly reduce fuel consumption for traditional vehicles and extend the range of electric cars, ultimately steering us toward greener, more sustainable transportation.”

This research was partially funded by the German Academic Exchange Service and the Department of Mechanical Engineering at MIT.

Photo credit & article inspired by: Massachusetts Institute of Technology