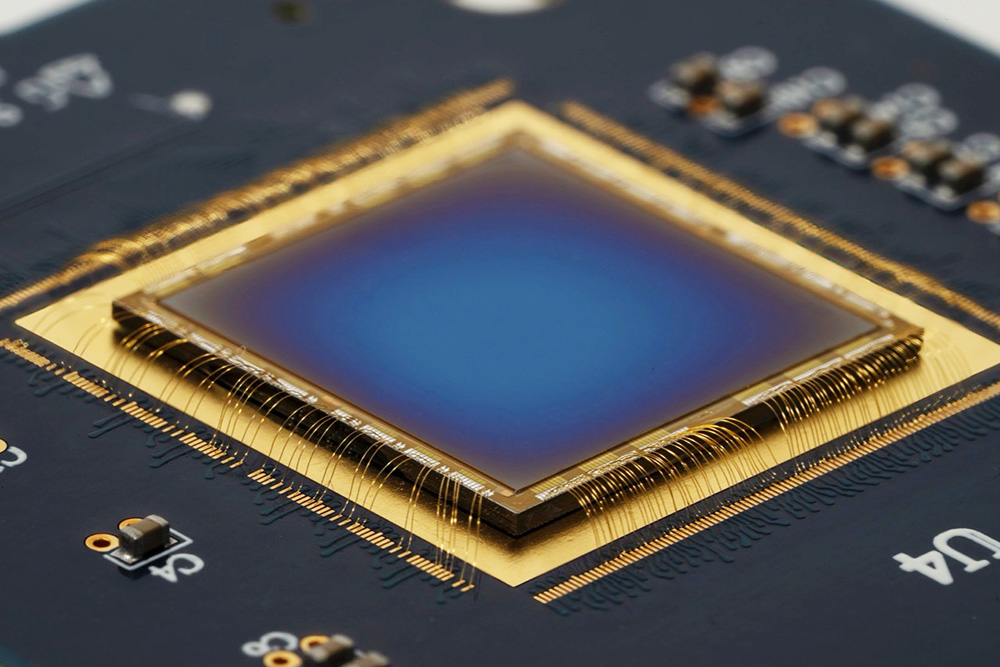

In the pharmaceutical manufacturing sector, accurately monitoring the characteristics of drying mixtures is crucial for producing high-quality medications and chemical compounds. Traditionally, two noninvasive methods have been employed: one involves imaging samples to count individual particles, and the other estimates particle size distribution (PSD) using scattered light. While imaging is thorough, it is also labor-intensive and results in increased waste, making the scattered light method a more appealing choice.

Recently, engineers and researchers from MIT have pioneered a new physics and machine learning-based approach utilizing scattered light. This innovative method enhances the manufacturing processes of pharmaceuticals, making them more efficient and accurate, thereby minimizing the incidence of failed product batches. A newly published open-access paper titled “Non-invasive estimation of the powder size distribution from a single speckle image,” released in the journal Light: Science & Applications, builds upon this progress and introduces an even swifter technique.

“Mastering the behavior of scattered light is one of the most significant endeavors in optics,” states Qihang Zhang, PhD ’23, an associate researcher at Tsinghua University. “Advancing our understanding of scattered light has enabled us to create a valuable tool for the pharmaceutical industry. Identifying and solving key issues through fundamental research is incredibly rewarding for our team.”

This study proposes an innovative PSD estimation strategy based on pupil engineering that significantly reduces the number of frames required for analysis. “Our machine learning model can determine the powder size distribution from just a single snapshot speckle image, cutting down reconstruction time from 15 seconds to an astonishing 0.25 seconds,” the researchers elaborate.

“Our primary contribution is accelerating the particle size detection process by a remarkable factor of 60, thanks to a comprehensive optimization of both our algorithm and hardware,” Zhang adds. “This high-speed probe can effectively monitor size variation in rapidly changing systems, paving the way for new models in the pharmaceutical industry concerning drying, mixing, and blending processes.”

By harnessing backscattered light from powder surfaces, this technique offers a cost-effective, noninvasive particle size probe. The compact and portable prototype is designed to work with most drying systems available on the market, provided there is an observation window. This real-time measurement system has the potential to revolutionize manufacturing processes, enhancing both efficiency and product quality. Previously, the absence of online monitoring hindered systematic studies of dynamic models in manufacturing, but this probe could introduce a new avenue for extensive research and modeling of particle size evolution.

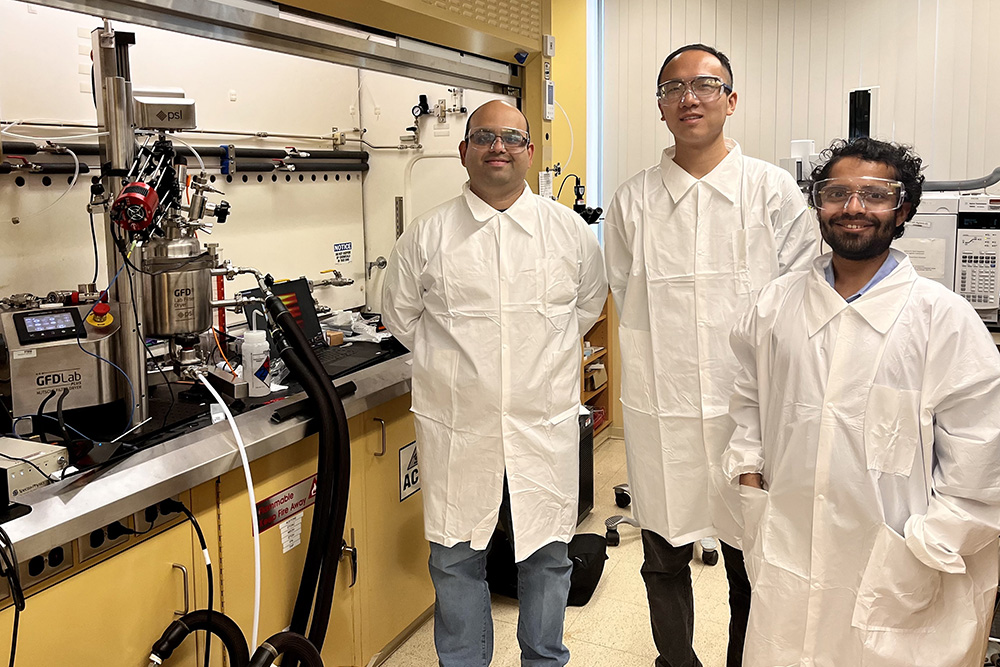

This collaborative effort between physicists and engineers stemmed from the MIT-Takeda program, involving experts from three MIT departments: Mechanical Engineering, Chemical Engineering, and Electrical Engineering and Computer Science. The paper’s senior author is George Barbastathis, a professor of mechanical engineering at MIT.

Photo credit & article inspired by: Massachusetts Institute of Technology