Every day at MIT, groundbreaking solutions to some of the globe’s most pressing challenges are being developed in labs, classrooms, and research centers. Many of these innovations transition from theoretical research to commercial applications with support from MIT’s extensive innovation and entrepreneurship (I&E) ecosystem, comprising over 85 specialized resources. A prime example is the Abdul Latif Jameel Water and Food Systems Lab (J-WAFS), which leverages MIT’s vast I&E expertise to assist researchers in bringing their transformative technologies to market through the J-WAFS Solutions grant program. By partnering with various I&E programs around the campus, J-WAFS equips MIT researchers for commercial success, enhancing the productivity, accessibility, and sustainability of water and food systems, with significant economic, environmental, and societal advantages.

Launched in 2015 with the backing of Community Jameel, a global organization fostering science and learning for community advancement, the J-WAFS Solutions program has awarded funding to 19 projects through grants of up to $150,000. Some projects have received renewals for an additional year of funding. All projects focus on vital issues related to water and food, reflecting a model inspired by the renowned grant program of MIT’s Deshpande Center for Technological Innovation. Initially administered by Deshpande Center staff, the J-WAFS Solutions program supports initiatives that have already reached the fundamental research and proof-of-concept stages. With technologies that are one to three years away from commercialization, grant recipients learn to identify potential markets and how their innovations can address future customer needs.

“At MIT, ingenuity drives the creation of inventions that can be translated into widespread applications,” states J-WAFS Director Professor John H. Lienhard V. “For successful commercialization of MIT technology, engineers must tackle numerous challenges beyond just functionality. MIT’s I&E network offers varied programs to assist researchers in developing technology readiness, exploring markets, conducting customer discovery, and initiating product design and development,” he explains. “This strong I&E framework has enabled many J-WAFS Solutions teams to establish startup companies by the end of their grants. Technologies supported by J-WAFS have profoundly impacted human welfare, illustrating how academic research can transform into innovative business solutions for a better world,” Lienhard adds.

Fostering I&E Collaborations

In addition to funding research initiatives, J-WAFS Solutions grants provide faculty, students, postdoctoral researchers, and research staff with foundational skills to translate their research into commercial products and businesses. As part of the grant process, researchers engage with mentors through MIT’s Venture Mentoring Service (VMS). VMS connects MIT entrepreneurs with carefully selected professionals who offer free, confidential mentorship and guidance to propel ideas into viable for-profit, for-benefit, or nonprofit ventures. Since its inception in 2000, VMS has supported over 4,600 MIT entrepreneurs across diverse industries through a dedicated group of nearly 200 volunteer mentors, providing unbiased advice to members of the MIT community, including alumni in the Boston area. J-WAFS Solutions teams have been guided by 21 mentors from various companies and nonprofits, who actively participate in project events and progress meetings during the grant period.

“Collaborating with VMS has been invaluable for my organization,” says Eric Verploegen PhD ’08, former research engineer in MIT’s D-Lab and founder of the J-WAFS spinout CoolVeg. Verploegen, along with professors Leon Glicksman and Daniel Frey, received a J-WAFS Solutions grant in 2021 to commercialize cold-storage chambers that utilize evaporative cooling to preserve produce in rural off-grid communities. He established CoolVeg in 2022 to enhance the accessibility and adoption of open-source evaporative cooling technologies through collaborations with businesses, research institutions, NGOs, and government bodies. “As a solo founder, having mentors to consult on strategic decisions and operational issues has been immensely beneficial,” Verploegen adds. Notably, even three years post-grant, one of the VMS mentors assigned to his team continues to provide guidance.

Participating in the Spark program is another prerequisite for Solutions grant teams. This free, three-week course serves as a vital entry point for researchers to explore the potential commercial value of their innovations. Spark is a component of the National Science Foundation’s (NSF) Innovation Corps (I-Corps), an immersive entrepreneurial training initiative that facilitates turning inventions into impactful solutions. In 2018, MIT received an NSF award establishing the New England Regional Innovation Corps Node (NE I-Corps), delivering I-Corps training throughout New England. Training sessions are open to researchers, engineers, scientists, and others eager to pursue customer discovery for their technology. Regularly scheduled, the Spark course assists participants in identifying markets and understanding customer requirements to competitively position their technologies, while also assessing adoption barriers and potential regulatory challenges. Since its initiation, over 1,200 MIT researchers have completed the NE-I-Corps program, launching 175 ventures, raising more than $3.3 billion in funding from grants and investors, and creating over 1,800 jobs.

Constantinos Katsimpouras, a research scientist in the Department of Chemical Engineering, participated in the NE I-Corps Spark program to gain insight into the customer landscape for a technology he developed with professors Gregory Stephanopoulos and Anthony Sinskey. Their team secured a J-WAFS Solutions grant in 2021 for a microbial platform that converts food waste from the dairy sector into valuable products. “As a scientist with no prior entrepreneurship experience, the program was crucial in introducing me to essential concepts for conducting customer interviews and adopting a new mindset,” Katsimpouras notes. “Crucially, it pushed me out of the lab to engage with potential customers and stakeholders, providing invaluable insights that deepened my understanding of my industry.” These interviews also facilitated connections with companies willing to supply resources needed to test and enhance their technology—a key step in scaling any laboratory innovation.

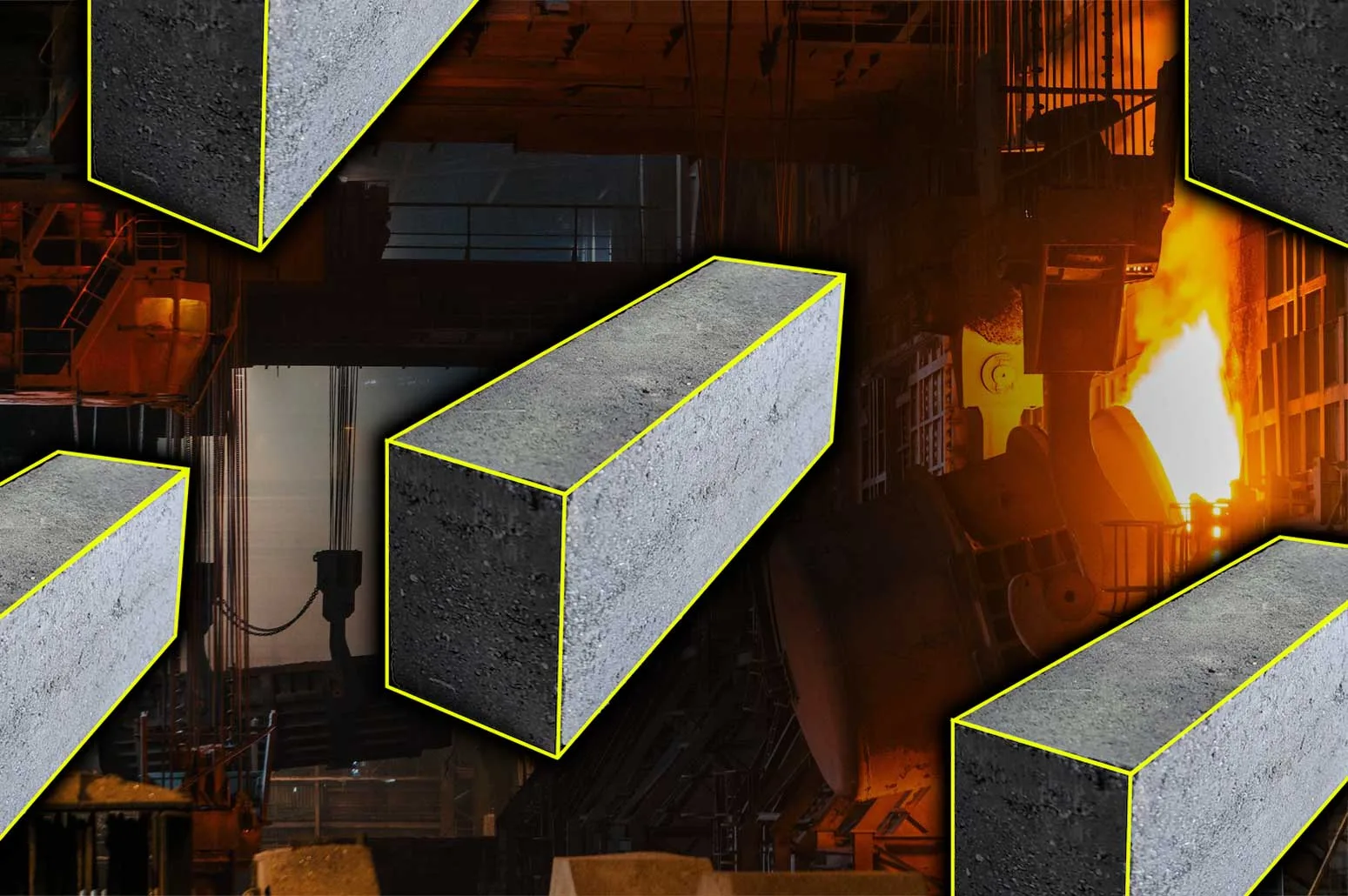

For Professor Cem Tasan’s research group in the Department of Materials Science and Engineering, the I-Corps program guided them toward applying for the J-WAFS Solutions grant. Tasan and postdoc Onur Guvenc are currently working on a project to manufacture formable sheet metal by consolidating steel scrap without the melting process, significantly reducing water usage compared to traditional methods. Before applying for the Solutions grant, Guvenc participated in NE I-Corps. “Engaging with potential customers through interviews helped challenge my initial market assumptions and uncover real customer needs,” Guvenc recalls. “This program illuminated the connection between water consumption and steel production processes, which ultimately guided our application for the 2023 J-WAFS Solutions Grant,” he states.

Upon completing the Spark program, participants may qualify to apply for the Fusion program, which awards microgrants of up to $1,500 to facilitate further customer discovery. This self-paced program requires teams to conduct twelve additional customer interviews and compile a presentation summarizing their key takeaways. Professor Patrick Doyle’s J-WAFS Solutions team successfully completed both Spark and Fusion, subsequently gaining entry into the NSF I-Corps National program with a $50,000 grant. This intensive program mandates teams to conduct an additional 100 customer discovery interviews over seven weeks. Located in the Department of Chemical Engineering, Doyle’s lab is developing a sustainable microparticle hydrogel system to rapidly eliminate micropollutants from water, while expanding their focus to higher-value purifications within the biopharmaceutical and amino acid manufacturing sectors. Devashish Gokhale PhD ’24 collaborated with Doyle on the scientific foundations of their project.

“Our technology has potential applications across diverse market segments, from individual consumers to large industries,” explains Gokhale. He emphasizes, “The I-Corps Spark program provided me with a robust framework to tackle our challenges. The mentorship was crucial in framing effective questions and identifying promising opportunities.” By the conclusion of Spark, the team had effectively pinpointed their most viable target markets, with additional workshops covering intellectual property issues proving beneficial during later discussions with MIT’s Technology Licensing Office.

Arjav Shah, a recent PhD graduate from MIT’s Department of Chemical Engineering and current MBA candidate at MIT Sloan, is at the forefront of the team’s commercialization efforts at hydroGel, a startup inspired by their research. After completing the Fusion program last fall, Shah aims to spearhead the company’s establishment. “I appreciate the hypothesis-driven methodology of the I-Corps program,” he shares. “This has enabled us to pinpoint our customers’ primary pain points, steering us towards achieving product-market fit.” Based on insights gathered during the program, the team has pivoted towards impact-oriented, high-value applications within the food processing and biopharmaceutical industries. Postdoc Luca Mazzaferro will lead the technical team at hydroGel alongside Shah.

In another venture, Qinmin Zheng, a postdoc in the Department of Civil and Environmental Engineering, is working with Professor Andrew Whittle and Lecturer Fábio Duarte. Zheng aims to participate in the Fusion course this fall to further develop their J-WAFS Solutions initiative, which seeks to commercialize an innovative sensor for monitoring algal species and detecting harmful algal blooms early. Following Spark, Zheng expresses enthusiasm for joining the Fusion program and potentially advancing to the National I-Corps program to explore market opportunities and mitigate future product development risks.

Driving Economic and Societal Impact

The commercialization of MIT-developed technologies is a key aspect of J-WAFS’s mission to ensure that research translates into tangible benefits for global water and food systems. Since its inception, the J-WAFS Solutions program has awarded 28 grants (including renewals), supporting 19 projects that tackle a broad spectrum of global water and food challenges. The program has disbursed more than $4 million to 24 professors, 11 research staff, 15 postdoctoral researchers, and 30 students at MIT. Remarkably, nearly half of all J-WAFS Solutions initiatives have culminated in spinout companies or commercialized products, with eight companies established to date plus two innovative open-source technologies.

Nona Technologies exemplifies a J-WAFS spinout addressing the need for innovative methods to produce freshwater for drinking. Desalination, traditionally reliant on large-scale reverse osmosis technologies, is revolutionized by Nona’s device, designed for remote off-grid locations. By utilizing electric current via ion concentration polarization (ICP) to separate salt and bacteria from water, their technology optimizes energy consumption. This innovative approach arose from the research by Jongyoon Han, a professor of electrical engineering and biological engineering, and research scientist Junghyo Yoon. Together with Sloan MBA graduate Bruce Crawford, they founded Nona Technologies to commercialize their lightweight, energy-efficient desalination solution.

“Initially, I thought that having the technology meant commercialization would follow on its own,” Crawford reveals. However, through participation in both Spark and Fusion programs, the team recognized that more groundwork was necessary. “In our first 24 interviews, we discovered that our two initial market ideas were not feasible in the short term, guiding us to viability in selecting our market approach,” Crawford continues. Nona Technologies has since claimed victory at MIT’s $100K Entrepreneurship Competition, garnered media coverage from outlets like Newsweek and Fortune, and expanded its team to enhance this technology for resource-limited regions with scarce access to clean drinking water.

Addressing food safety, J-WAFS researchers innovate by integrating molecular engineering, nanotechnology, and artificial intelligence to advance pathogen testing in food. Professors Tim Swager and Alexander Klibanov, awarded one of the inaugural J-WAFS Solutions grants, developed a state-of-the-art sensor aimed at detecting food pathogens. Utilizing specialized droplets that react to target bacteria, the sensor enables precise detection of harmful contaminants in food. In 2018, Swager founded Xibus Systems Inc. to commercialize this crucial technology, thereby advancing food safety and bolstering public health and economic security.

“Involvement with the J-WAFS Solutions Program has been instrumental for us,” asserts Swager. “It has bridged the gap between academia and industry, enabling us to refine our work toward a practical application,” he adds. In 2022, Xibus successfully launched XiSafe, a product capable of faster, more sensitive detection of contaminants like salmonella and listeria compared to existing food testing technologies. This innovation has the potential to save food processors billions annually and prevent thousands of food-borne illnesses.

Companies emerging from J-WAFS Solutions have attracted nearly $66 million in venture capital and other funding. Recently, J-WAFS spinout SiTration announced an $11.8 million seed round. Jeffrey Grossman, a professor in MIT’s Department of Materials Science and Engineering, was an early grantee for his initiative focused on developing cost-effective, energy-efficient desalination filters, which led to the creation of nanoporous membranes and the formation of two spinout companies: Via Separations and SiTration. Co-founded by Brendan Smith PhD ’18, who was part of the original J-WAFS team, SiTration aims to advance membrane technology, optimizing resource utilization in industrial wastewater treatment, resource extraction from recycled electric vehicle batteries, and working with Rio Tinto for handling harmful wastewater at mining sites.

However, the impact of J-WAFS research extends beyond just spinout companies. The ECC Vial, a portable, low-cost method for detecting E. coli in water, exemplifies this by improving public health. Developed by MIT D-Lab Lecturer Susan Murcott and Professor Jeffrey Ravel, this test kit was backed by a J-WAFS Solutions grant in 2018 to promote sanitary drinking water in Nepal, where identifying contaminated wells can be challenging. By the end of their grant, the team had produced approximately 3,200 units, distributing around 2,350, benefiting about 12,000 people in Nepal and providing local training in best manufacturing practices.

“Following one’s dreams while serving others is vital,” emphasizes Murcott. While financial success is crucial for any venture, be it a company or a product, the social impact remains equally significant. This philosophy underpins J-WAFS’s mission. “Undertake endeavors that are worthwhile and transformative for people’s lives,” Murcott conveys.

As J-WAFS commemorates its 10th anniversary, the organization eagerly anticipates the continuation of fruitful collaborations with MIT’s I&E programs to advance knowledge and develop impactful solutions for global water and food systems.

To discover more about the J-WAFS Solutions program and learn about innovation and entrepreneurship at MIT, visit our website.

Photo credit & article inspired by: Massachusetts Institute of Technology