Methane, while less prevalent than carbon dioxide, plays a significant role in exacerbating global warming due to its remarkable ability to trap heat in the atmosphere. Recognizing this challenge, MIT chemical engineers have developed an innovative catalyst capable of converting methane into valuable polymers, potentially curbing greenhouse gas emissions.

“Managing methane effectively has been a persistent challenge,” explains Michael Strano, the Carbon P. Dubbs Professor of Chemical Engineering at MIT and the lead author of the study. “It serves as a carbon source, and our goal is to prevent its release into the atmosphere while transforming it into useful products.”

The breakthrough catalyst operates at room temperature and atmospheric pressure, facilitating more economical implementation at methane emission sources, such as power plants and agricultural sites.

Lead authors Daniel Lundberg PhD ’24 and postdoc Jimin Kim contributed to the study, which recently appeared in Nature Catalysis. They were joined by former postdoc Yu-Ming Tu and postdoc Cody Ritt in this research endeavor.

Understanding Methane Emissions

Methane is primarily generated by methanogenic bacteria, which thrive in environments like landfills, swamps, and decaying organic material. Additionally, agriculture significantly contributes to methane emissions, as does the natural gas supply chain. Overall, methane is estimated to account for approximately 15% of the increase in global temperatures.

Molecularly, methane comprises one carbon atom and four hydrogen atoms, making it an ideal candidate for producing a variety of beneficial products, including polymers. However, converting methane into other compounds presents challenges, as traditional methods often require high temperatures and pressures.

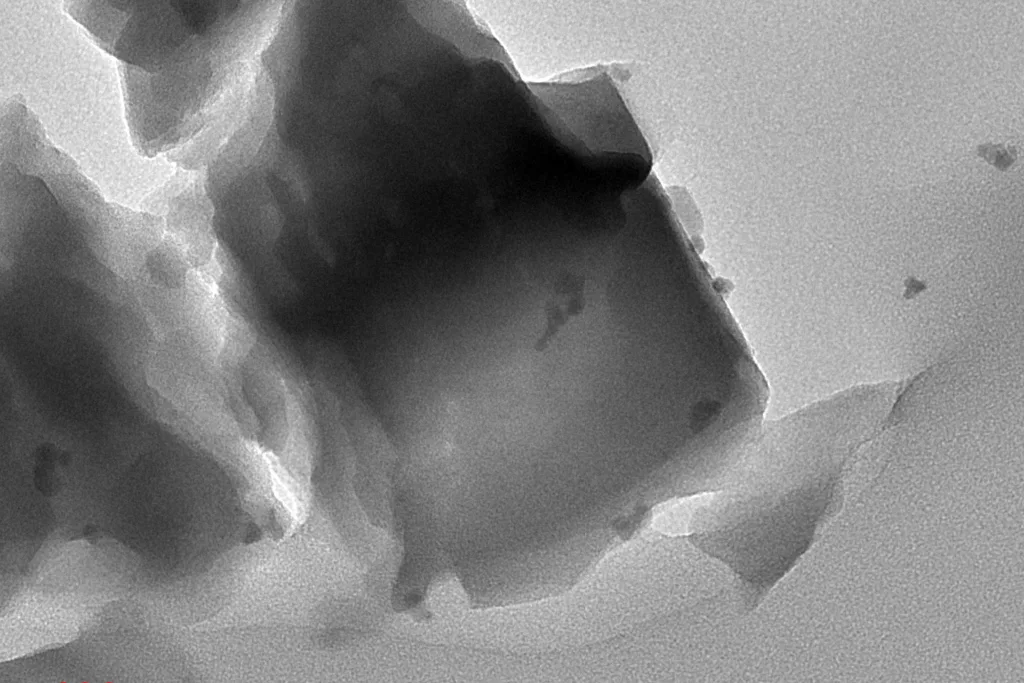

To overcome these energy demands, the MIT research team created a hybrid catalyst consisting of a zeolite and a natural enzyme. Zeolites, which are abundant and cost-effective clay-like minerals, have previously been utilized to catalyze methane conversion into carbon dioxide.

In this innovative approach, the researchers employed a specific zeolite known as iron-modified aluminum silicate alongside an enzyme called alcohol oxidase, which aids in the oxidation of alcohols in organisms like bacteria and plants.

This hybrid catalyst engages in a two-step reaction: the zeolite transforms methane into methanol, and subsequently, the enzyme converts methanol into formaldehyde. Notably, this process generates hydrogen peroxide, which is integrated back into the zeolite to supply oxygen for methane conversion.

Significantly, this catalytic process occurs under mild conditions—room temperature and atmospheric pressure. The catalyst particles are suspended in water, which can capture methane from the air. The researchers envision potential applications for this catalyst, such as coating surfaces or direct integration into existing infrastructure.

“Unlike other systems that demand high energy inputs and use expensive hydrogen peroxide for methane oxidation, our enzyme generates hydrogen peroxide from oxygen, allowing for a more cost-effective and scalable method,” Kim states.

The amalgamation of enzymes and artificial catalysts epitomizes what’s termed “hybrid catalysis,” a concept championed by Damien Debecker, a professor at the Institute of Condensed Matter and Nanosciences at the University of Louvain, Belgium. He remarks, “Combining these two types of catalysts can be intricate, as they function optimally under distinct conditions. By breaking these barriers and mastering the integration of chemo-enzymatic processes, hybrid catalysis holds the key to advancing complex reaction systems efficiently.”

Turning Methane into Polymers

Upon generating formaldehyde, the research team demonstrated that this compound could be utilized to synthesize polymers by introducing urea, a nitrogenous substance prevalent in urine. The resultant polymer, known as urea-formaldehyde, finds applications in various products, including particle board and textiles.

Furthermore, the research team envisions the incorporation of this catalyst into pipelines used for natural gas transportation. By employing the catalyst within these pipes, it could facilitate the creation of a self-healing polymer, effectively sealing cracks—common sources of methane leaks. Additionally, it could serve as a coating for surfaces exposed to methane, allowing for the recovery of polymers for manufacturing.

Strano’s lab is also exploring catalysts capable of removing carbon dioxide from the atmosphere, which could subsequently be combined with nitrate to produce urea, complementing the formaldehyde generated by the zeolite-enzyme catalyst to create urea-formaldehyde.

This groundbreaking research received support from the U.S. Department of Energy.

Photo credit & article inspired by: Massachusetts Institute of Technology