The construction industry faces a significant challenge: the staggering amount of waste it generates. Recent data indicates that in 2018 alone, the United States produced 600 million tons of construction and demolition waste. In comparison, the European Union recorded 820 million tons, and China exceeded 2 billion tons. This alarming figure highlights the urgent need for the construction sector to shift toward a circular economy—a sustainable model designed to reduce waste while maximizing material reuse and efficiency.

Current practices demonstrate a linear economy characterized by a “take-make-dispose” model. Conversely, the circular economy presents a transformative opportunity with its “make-use-reuse” paradigm, aiming to significantly lessen environmental impacts.

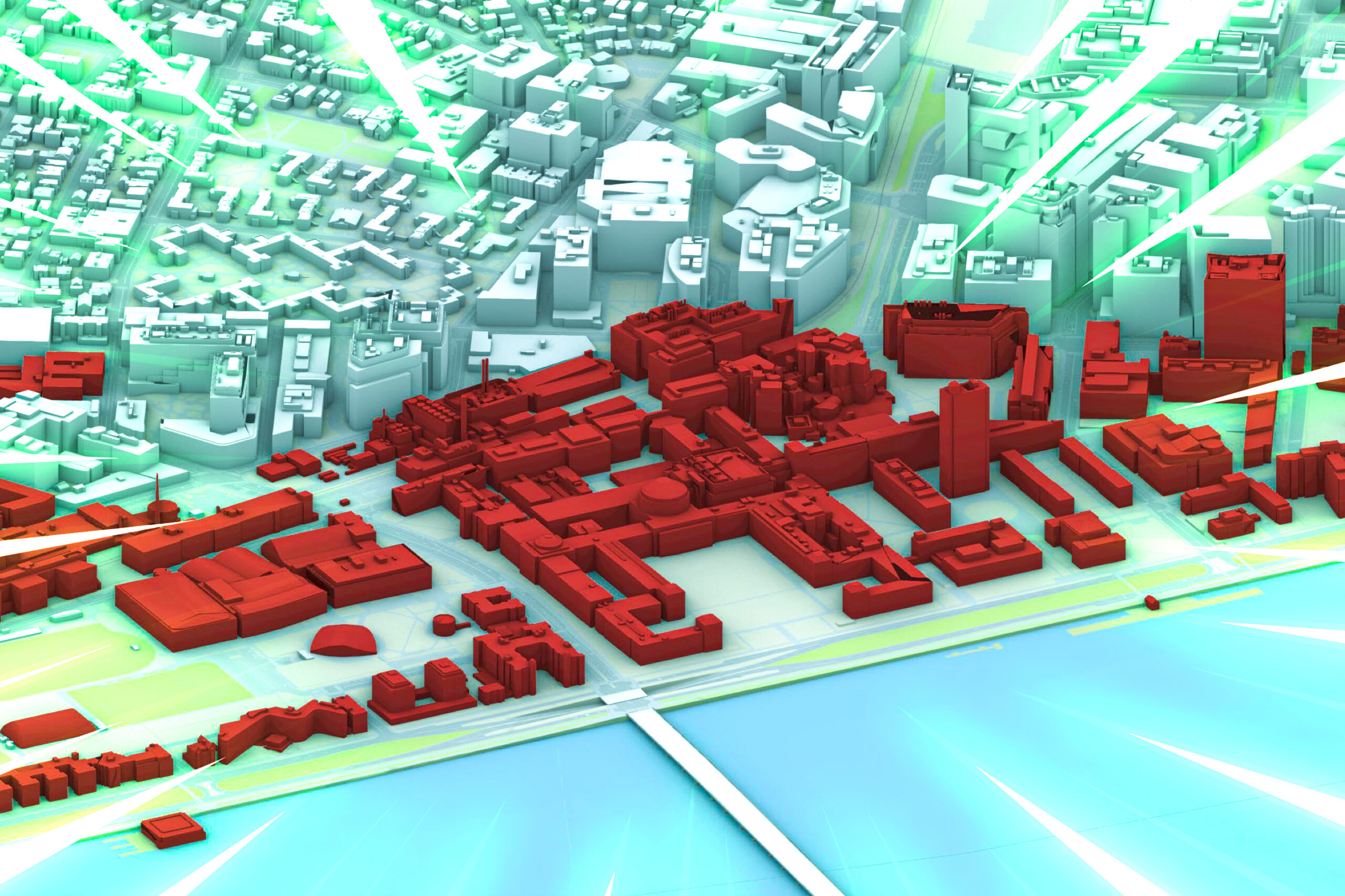

A team at the Massachusetts Institute of Technology (MIT) is investigating how to facilitate this crucial transition towards circularity in the built environment. Their open-access study seeks to gauge stakeholders’ perceptions of circularity and their willingness to invest in these new methodologies.

“This research is an initial step in understanding the motivations within the industry and how aligning these motivations can lead to broader adoption of circular practices,” explains lead author Juliana Berglund-Brown, a PhD student at MIT’s Department of Architecture.

Stakeholder Perspectives on Circularity

In their survey, the research team engaged three key groups from North America, Europe, and Asia, including material suppliers, design and construction teams, and real estate developers. Collaborators on this project include Akrisht Pandey, ’23; Fabio Duarte, associate director of the MIT Senseable City Lab; Raquel Ganitsky, a fellow in the Sustainable Real Estate Development program; Randolph Kirchain, co-director of the MIT Concrete Sustainability Hub; and Siqi Zheng, the STL Champion Professor of Urban and Real Estate Sustainability.

Despite an increased awareness of practices promoting reuse among construction stakeholders, the large-scale adoption of circular methods remains limited. This hesitancy is attributed to multiple factors, including regulatory constraints and the financial interests of real estate developers.

The study identifies variables influencing the perceived barriers to circularity based on the roles of industry stakeholders. Design and construction teams highlight a lack of client interest and standardized assessment methods as main concerns, while material suppliers face challenges related to logistics and supply risk. Conversely, real estate developers primarily worry about higher costs and structural evaluations.

Nevertheless, survey respondents expressed a readiness to invest, with developers indicating an average willingness to accept an additional 9.6% in construction costs to achieve at least a 52.9% reduction in embodied carbon emissions. Incentives like tax breaks emerged as particularly appealing mechanisms to address these cost premiums.

Moving Towards Circular Practices

The research underscores the necessity for dialogue between design teams and developers, as well as the exploration of practical solutions to existing challenges. “Embracing circularity opens up numerous opportunities for value generation and profit,” says Berglund-Brown. “If cost is a concern, let’s introduce financial incentives or develop strategies that provide them.”

Industry roles significantly shape motivations for adopting circular practices. Future net-zero targets resonate with developers and design teams alike, with government regulations ranking as the third-most crucial influencing factor across all respondent types.

“A market driver is essential for the construction sector to fully embrace circularity,” asserts Berglund-Brown. “Whether through carrots or sticks, stakeholders need incentives for meaningful adoption.”

The pivotal role of policy in driving change is evident, especially after the introduction of emissions-reducing regulations, which have catalyzed advancements in low operational carbon building practices. Notable examples of such legislation include Local Law 97 in New York City and the Building Emissions Reduction and Disclosure Ordinance in Boston. These regulatory frameworks can serve as models to inspire similar strategies aimed at reducing embodied carbon.

Berglund-Brown proposes that municipalities could enact ordinances requiring the deconstruction of buildings, making it possible to salvage materials for reuse rather than disposal—a shift that could transform the construction landscape. Top-down policies may be instrumental in steering the supply chain toward the reprocessing of materials generally considered waste.

Further complications in implementing circular systems at scale include the risks associated with reusing materials and disrupting established design practices.

“Our work focuses on finding the best ways to drive this transition, even amidst uncertainty,” remarks Berglund-Brown. “Moreover, researchers can play a vital role in mitigating risks—such as by developing reuse standards.”

Pioneering Innovations at MIT

MIT researchers are known for challenging the status quo, exemplified by initiatives like Pixelframe, a groundbreaking “smart kit of parts” designed for modular concrete reuse. This innovative system facilitates the disassembly and rebuilding of structures, promoting material efficiency and versatility.

Developed by Caitlin Mueller’s research team, Pixelframe is adaptable for various applications, ranging from housing to warehouses. Each interlocking precast concrete module, termed Pixels, carries a material passport, enabling tracking throughout its lifecycle.

Mueller emphasizes that circularity can function effectively on a large scale within the built environment by prioritizing designs that allow for disassembly, flexible configurations, and upfront carbon and cost efficiency. “This is a solution that can be implemented today, compliant with building codes,” said Mueller during a keynote at the recent MCSC Annual Symposium, where industry leaders and MIT community members convened to discuss actionable solutions for climate and sustainability challenges. “We hold the potential for substantial carbon reduction as a viable alternative to traditional construction practices.”

Pixelframe recently received funding from the Massachusetts Clean Energy Center (MassCEC) to advance its commercialization, representing a key step in realizing circular economy innovations. “It’s our mission to equip climate leaders with necessary resources to bring their technologies to market and make a global impact,” stated MassCEC CEO Emily Reichart in a press release.

Additionally, support for circular innovations has gained momentum thanks to a historic climate legislation from the Biden administration. The Environmental Protection Agency recently granted funding for projects focused on advancing the reuse of structural heavy-section steel, awarded to Berglund-Brown—whose doctoral research aims to scale this practice—alongside John Ochsendorf, a professor in civil and environmental engineering and architecture at MIT.

“We are on the cusp of exciting developments in this field,” remarks Berglund-Brown. “To any practitioners interested in joining this movement—please reach out.”

This research is partially funded by the MIT Climate and Sustainability Consortium.

Photo credit & article inspired by: Massachusetts Institute of Technology