Steel stands as one of the most indispensable materials in the modern world. From towering skyscrapers to automobiles, airplanes to bridges, steel plays a crucial role in countless aspects of our daily lives. However, the conventional methods of steel production are notorious for their environmental impact.

The primary method of steelmaking involves extracting iron ore, processing it in a blast furnace with coal, and refining it in an oxygen furnace to eliminate excess carbon and impurities. This traditional steel production method is responsible for approximately 7 to 9 percent of global greenhouse gas emissions, making it one of the most polluting industries on the planet.

In response to this environmental challenge, Boston Metal is pioneering an innovative solution for the steel industry through a groundbreaking electrochemical technique known as molten oxide electrolysis (MOE). This method streamlines the steelmaking process, significantly reducing emissions and producing oxygen as its only byproduct.

Founded by MIT Professor Emeritus Donald Sadoway along with Professor Antoine Allanore and PhD alumnus James Yurko, Boston Metal is already utilizing MOE to recover valuable metals from mining waste at its Brazilian operation, Boston Metal do Brasil. This initiative enables the company to scale its technology commercially and forge essential partnerships with mining operators. Additionally, a prototype MOE reactor has been established at its headquarters in Woburn, Massachusetts, to produce green steel.

Despite its name, Boston Metal has true global aspirations. The company has successfully raised over $370 million from investors spanning Europe, Asia, the Americas, and the Middle East, with plans for rapid expansion to revolutionize steel production worldwide.

“There’s a growing global consensus that immediate action is necessary, and technology solutions like ours are key to moving away from outdated practices,” states Boston Metal’s Chief Scientist and former MIT postdoc, Guillaume Lambotte. “Climate change increasingly influences our lives, placing pressure on everyone to act quickly.”

A Long Journey of Innovation

Sadoway has pursued electrochemical processes since the 1980s with a focus on aluminum production. His early research aimed at eliminating the consumable anodes that generate carbon dioxide as a byproduct. While exploring this area, he conceptualized an electrochemical method for producing iron, the foundational element for steel.

It wasn’t until 2012 that Sadoway and Allanore, then a postdoctoral researcher at MIT, identified a cost-effective iron-chromium alloy that could serve as a stable anode material, making the commercial viability of the process possible while also producing oxygen as a byproduct. This discovery led to the founding of Boston Metal in partnership with Yurko.

“Our initial research and foundational technologies emerged from MIT,” explains Lambotte. “We built on patented research licensed from MIT’s Technology Licensing Office.”

Shortly after Sadoway’s team published their pivotal 2013 paper in Nature detailing the MOE platform, Lambotte joined the company, helping transition their laboratory successes into commercial production capabilities.

“We went from small-scale experiments to a company capable of producing hundreds of kilograms, and soon tons of metal,” adds Lambotte.

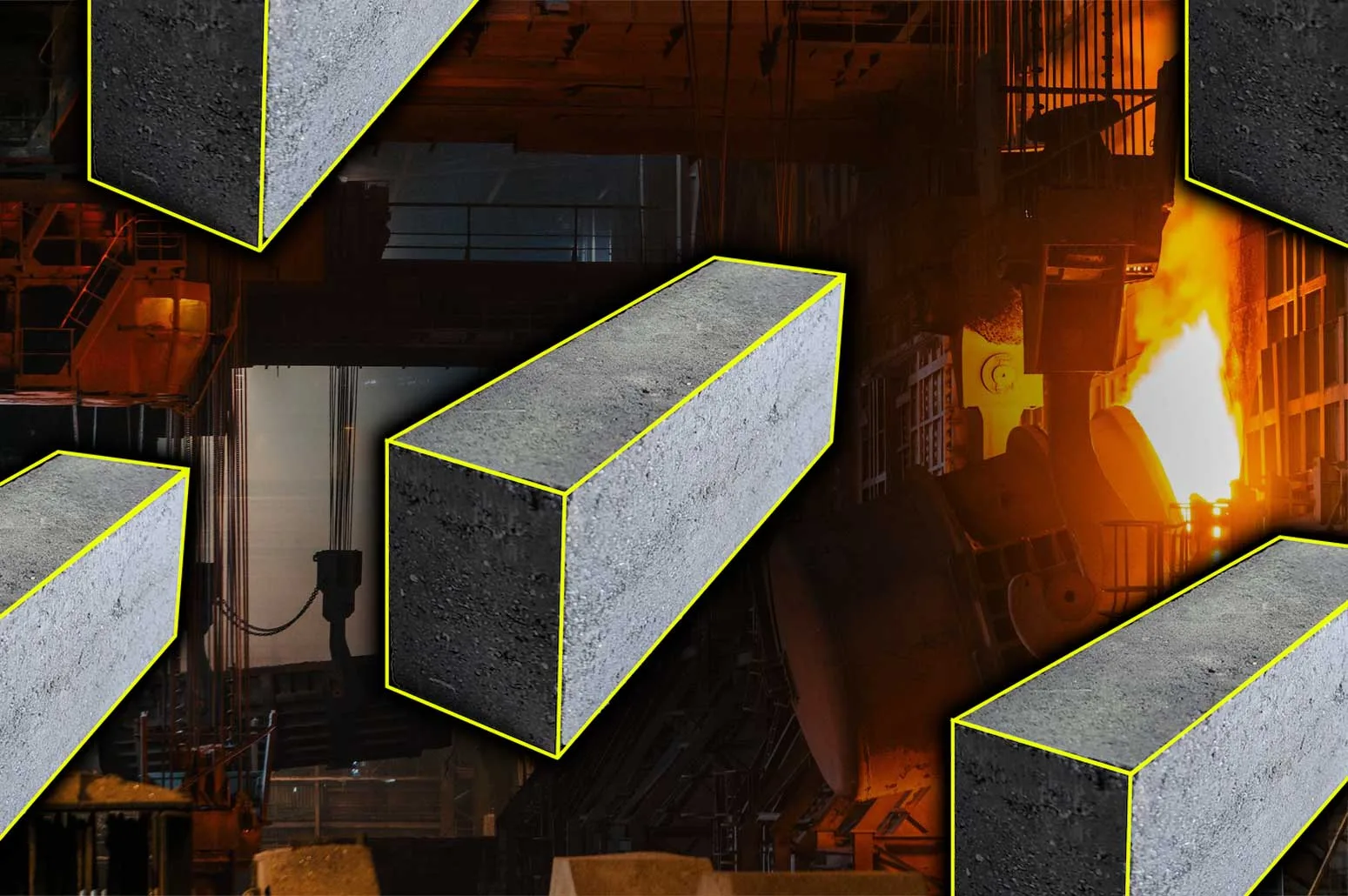

The molten oxide electrolysis process utilized by Boston Metal occurs in modular MOE cells, each comparable in size to a school bus. Iron ore is introduced into the cell containing a cathode (the negative terminal) and an inert anode submerged in a liquid electrolyte. As electricity flows between these two components at temperatures around 1,600 degrees Celsius, the iron oxide bonds in the ore are broken down, yielding pure liquid metal that can be tapped off easily. The only byproduct of the reaction is oxygen, and the entire process circumvents the use of water, hazardous chemicals, or costly precious-metal catalysts.

The capacity of each cell is dictated by its electrical current. With roughly 600,000 amps, a single cell has the potential output of up to 10 tons of metal daily. Steel manufacturers can license Boston Metal’s technology and deploy a suitable number of cells to meet their specific production needs.

Moreover, Boston Metal is leveraging MOE to support mining companies in extracting high-value metals from mining waste, which typically requires expensive treatment or storage solutions. According to Lambotte, the technology holds promise for producing a range of different metals in the future, and the company has recently been chosen to negotiate grant funding aimed at producing chromium metal—essential for several clean energy applications—in West Virginia.

“Globally, many feedstocks for metal production are oxides, so if it’s an oxide, there’s potential for us to utilize that source,” Lambotte explains. “The demand for effective solutions to decarbonize the metal industry is creating significant excitement around MOE’s applications.”

Enormous Potential Ahead

Boston Metal’s revolutionary approach to steel decarbonization is set to achieve commercial-scale operations by 2026, although the Brazilian facility is already actively familiarizing the steel industry with MOE.

“This is an opportunity for the metal industry to engage with MOE and understand its benefits,” emphasizes Lambotte. “It’s critical to foster connections and facilitate the spread of new technologies.”

Notably, the Brazilian plant operates entirely on renewable energy.

“We stand to gain from the global push towards decarbonizing the energy sector,” Lambotte states. “Our technology complements that vision. Genuine green steel necessitates access to green electricity, so we anticipate deploying our solution in regions where clean energy is abundantly available.”

The team at Boston Metal is enthusiastic about the potential of MOE across the metals industry but remains focused predominantly on the vital task of drastically reducing emissions from steel production.

“With steel accounting for about 10 percent of global emissions, that is our guiding principle,” Lambotte concludes. “Industries are making commitments to reduce carbon footprints and achieving net-zero goals, making the search for viable technology solutions in steel manufacturing more urgent than ever.”

Photo credit & article inspired by: Massachusetts Institute of Technology