Cochlear implants, remarkable electronic devices designed to restore a sense of sound for individuals who are deaf or hard of hearing, have transformed the lives of over a million people globally, according to the National Institutes of Health. Yet, the current design of cochlear implants requires external hardware, typically situated on the side of the head, which can limit activities like swimming, exercising, or even sleeping.

In a significant advancement towards developing a fully internal cochlear implant, a collaborative research team from MIT, Massachusetts Eye and Ear, Harvard Medical School, and Columbia University has developed an innovative implantable microphone that matches the performance of external hearing aid microphones. This breakthrough tackles one of the most significant challenges in creating a completely internalized cochlear implant.

The new microphone utilizes a biocompatible piezoelectric material and is adept at capturing minuscule vibrations on the underside of the eardrum. Piezoelectric materials generate an electric charge when compressed or stretched. To optimize the device’s capabilities, researchers also designed a low-noise amplifier that improves the sound signal while reducing electronic noise interference.

While the journey to a fully functional internal microphone paired with a cochlear implant is ongoing, the team is eager to refine and test this prototype, building on a decade of research initiated at MIT and Massachusetts Eye and Ear.

“It starts with the ear doctors who work to improve hearing and recognize the need for advancement in technology. Their collaboration with our team has been essential to our progress,” notes Jeffrey Lang, the Vitesse Professor of Electrical Engineering and co-senior author of a paper discussing the microphone.

Lang’s coauthors include Emma Wawrzynek and Aaron Yeiser, both co-lead authors and graduate students, along with researchers from Mass Eye and Ear, Columbia University, and Harvard Medical School. This groundbreaking research has been published in the Journal of Micromechanics and Microengineering.

Addressing the Limitations of Cochlear Implants

Traditionally, cochlear implant microphones are affixed to the side of the head, which prevents users from benefiting from the natural sound filtering and localization capabilities of the outer ear. Fully implantable microphones present numerous advantages, yet many prototypes currently in development struggle to accurately capture soft sounds across a wide frequency range.

The innovative microphone targets the umbo, a part of the middle ear that vibrates in a specific manner, simplifying the task of detecting these minimal movements. Despite the umbo’s significant range of motion, its vibrations are only a few nanometers, making measurement quite complex.

Moreover, any implantable sensor needs to be biocompatible and durable enough to resist the body’s humid environment, further complicating the choice of materials.

“Our vision is for this device to be implanted simultaneously with the cochlear implant, enhancing the efficiency of the surgery while ensuring that the internal structures of the ear remain undisturbed,” explains Wawrzynek.

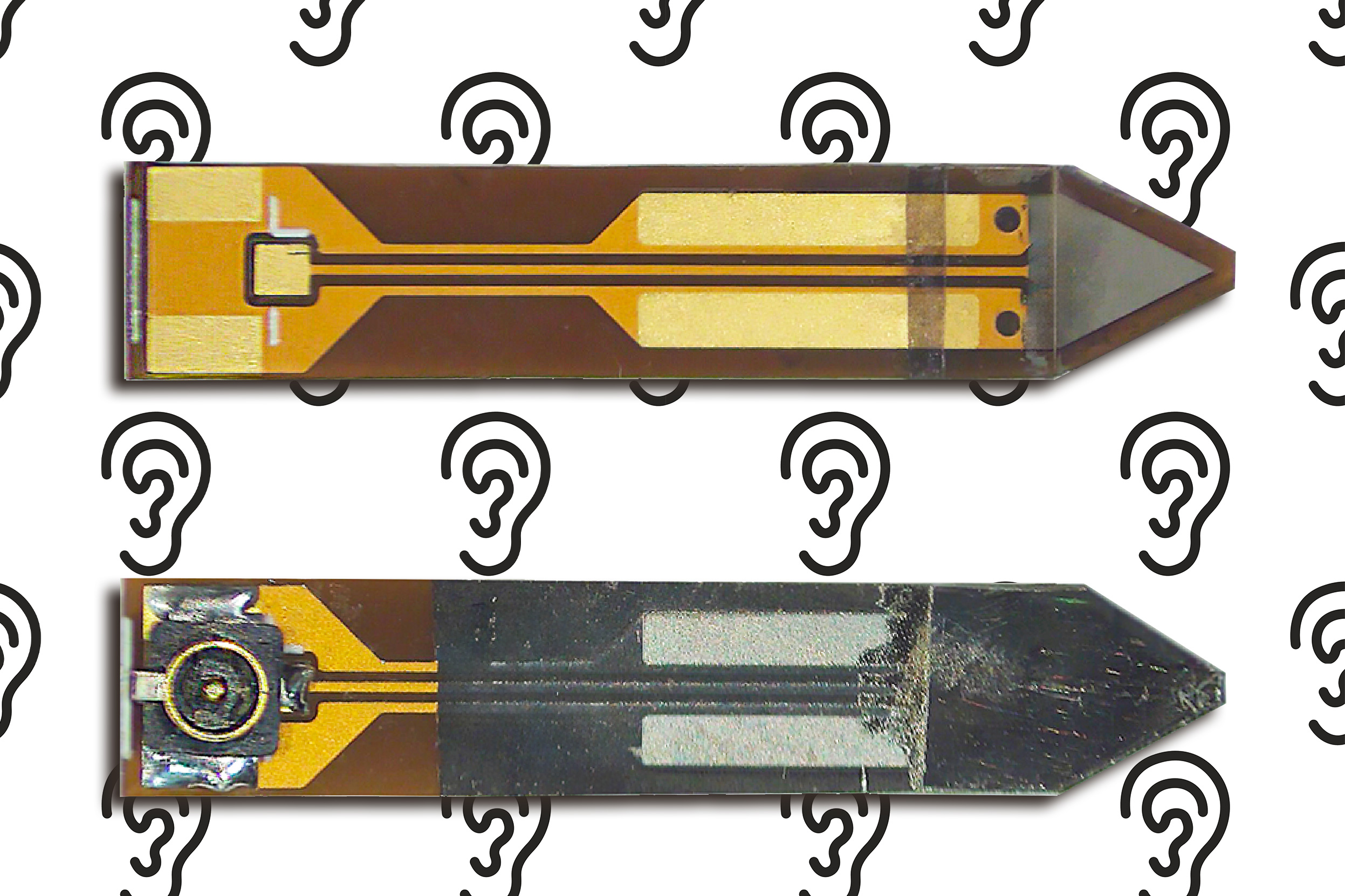

Through meticulous engineering, the team succeeded in creating the UmboMic, a triangular sensor measuring 3 by 3 millimeters and composed of two layers of the biocompatible piezoelectric material polyvinylidene difluoride (PVDF). This microphone, about the size of a grain of rice and 200 micrometers thick, can seamlessly interface with the umbo. When the umbo vibrates, it presses against the piezoelectric material, causing the PVDF layers to bend and generate measurable electric charges.

Enhancing Sound Amplification

The team employed a “PVDF sandwich” structure to minimize noise. This design allows for the cancellation of electrical interference, which affects both PVDF layers equally and thus can be subtracted to reveal the true signal.

Although PVDF offers many advantages, it posed fabrication challenges; the material’s properties diminish when exposed to high temperatures, yet high heat is necessary for the deposition of titanium, another biocompatible material. Wawrzynek ingeniously solved this issue by utilizing a gradual titanium deposition technique along with a heat sink to cool the PVDF.

The signal amplification was another hurdle; the umbo’s tiny vibrations necessitated a low-noise amplifier capable of conserving power. When a suitable model couldn’t be found, the researchers engineered their own.

Testing the prototype on human ear bones from cadavers showed that the UmboMic performed well within the intensity and frequency ranges of human speech, with a low noise floor that enables the detection of faint sounds against background noise.

“What’s fascinating is that the frequency response varies based on individual ear anatomy, as the umbo vibrates differently in different ears,” Wawrzynek points out, indicating the need for further studies.

The team is preparing to initiate live animal studies to advance their research and assess the UmboMic’s behavior once implanted. They are also exploring methods to encapsulate the sensor to ensure biocompatibility for extended durations, aiming to balance flexibility with durability to capture sound accurately.

“This research demonstrates the necessary wide-band response and low noise levels essential for effective acoustic sensing. The findings are unexpected, as they rival commercial hearing aid microphones, highlighting the potential of this approach. Future advancements may require smaller sensors and lower power electronics to improve implantation and battery longevity,” comments Karl Grosh, a mechanical engineering professor at the University of Michigan.

This research received funding from the National Institutes of Health, the National Science Foundation, the Cloetta Foundation in Zurich, Switzerland, and the Research Fund of the University of Basel, Switzerland.

Photo credit & article inspired by: Massachusetts Institute of Technology